Keihin TOISHI

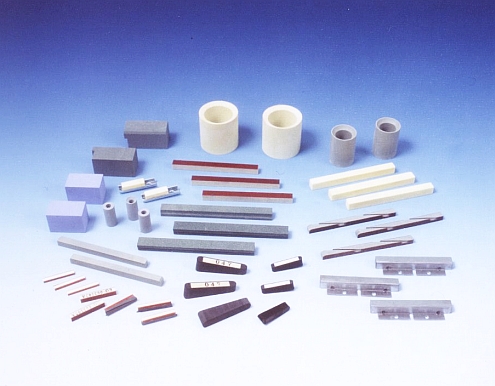

Honing Stones

Honing stones are used for accurate and efficient honing of inner surfaces of holes.

Recommendation of Honing Stones

|

Work material

Surface Roughness |

Steel C less than 0.3% | Steel C more than 0.3% | Alloy Steel | Stainless Steel |

|---|---|---|---|---|

| 3.0~6.0S | WA150-180RH70(+S) QB180-220H(+S) |

WA150-180RH60(+S) QB180-220J(+S) |

WA又はMA80-150RH30(+S) QB180-220H(+S) |

WA180RH40(+S) QB180-220I(+S) |

| 1.5~3.0S | WA220RH60(+S) QB220J(+S) |

WA220RH50(+S) QB220J(+S) |

WA220RH30(+S) QB220I(+S) |

WA220RH30(+S) QB220I(+S) |

| 0.8~1.5S | WA320RH50(+S) | WA280-320RH40(+S) | GC280-320RH30(+S) | GC280 RH2 GC120M UP |

| 0.2~0.8S | WA800 RH90 GC320RH70 |

GC600 RH90 GC320RH60 |

GC600 RH30 | GC600 RH10 GC120UP |

| Standard Cast Iron | Special Cast Iron | Aluminum Alloy | Honing Allowance | |

| GC120-180RH80(+S) QB180-220K(+S) |

GC120-150RH60(+S) QB180-220J(+S) |

GC80M UP | 0.10~0.50 | |

| GC220RH70(+S) QB220H(+S) |

GC220RH50(+S) QB220J(+S) |

GC120M UP | 0.05~0.10 | |

| GC320RH60 | GC320RH40 | GC220M UP | 0.01~0.05 | |

| GC800 RH40 GC320RH70 |

GC800 RH30 GC320RH60 |

GC320M UP | 0.01以下 | |

(+S) represents sulfur treated. UP represents water/grease resistant sponge grinding wheel.

At a honing work, roughness of the surface finish differs greatly depending upon the honing machine and work condition. On selecting a honing stone, please inform of following items and consult thoroughly about the selection.

1.Workpiece

1.Material

2.Heat Treatment

3.Shape and Dimension

4.Honing Allowance

5.Surface Roughness Requirement

6.Crosshatch angle

2.Honing Machine

1.Name of the machine

2.Honing Oil

3.Working Conditions

1.Rotation Speed (Operating Speed)

2.Stroke Speed

3.Grinding Pressure

4.Work Timing